ZIRCONIUM (Saint Gobain)

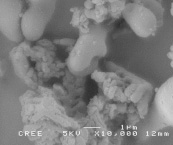

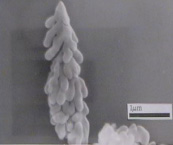

AN ORIGINAL DENDRITIC GRAIN MORPHOLOGY

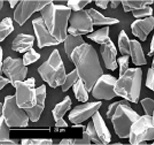

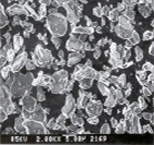

IN COMPARISON TO STANDARD ABRASIVE MATERIALS

Fused Zirconia

Silicon Carbide

Levigated Alumina

* A unique thermal and chemical manufacturing process, Enjoying 30 Years of Industrial experience, guarantying reliablity and consistency.

High chemical purity

| Zirgrip-1 | Zirgrip-3 | Zirgrip-10 | Zirgrip-30 | |

|---|---|---|---|---|

| SiO₂ | 0.50 | 0.90 | ||

| Na₂ O | 0.20 | 0.05 | ||

| AL₂ O₃ | 0.10 | 0.20 | ||

| TiO₂ | 0.10 | |||

| Fe₂ O₃ | 0.04 | |||

| Cao | 0.03 | |||

| U+Th | <0.05% (Typically 0.04%) | |||

Fine powder with narrow perticle size distribution

| Zirgrip-1 | Zirgrip-3 | Zirgrip-10 | Zirgrip-30 | |

|---|---|---|---|---|

| D50 (μm) | 1.5 | 3 - 4 | 12 - 14 | 90 -95 |

| SSA (m²/g) | 3.2 | 2.8 | 5 - 6 | 5 - 6 |

ZIRGRIP : KEY FIGURES

- Dendritic grains morphology makes it an unique product

- U + Th < 500 ppm

- Used by major brake pads makers for their commercial brake pad formulations (700-1000 tons consumption, growing)

- Under qualification at all major brake pad manufacturers

- Made outside of China no export license is required

- Benefits from the long industrial experience of Saint-Gobain in production of consistent & reliable high performance materials