STYLAC - AS & ABS (Asahi Kasei )

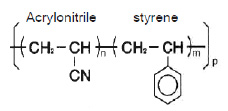

AS(SAN)

Acrylonitrile-styrene resin

- Characteristic: Chemical resistant, Strength, Heat resistant

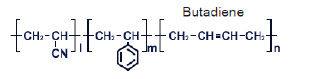

ABS

Acrylonitrile-butadiene-styrene resin

- Characteristic : Impact, Chemical resistant, Gloss

Features

We have line up of wide range of AN/ST ratio for Asahi Kasei polymerization technology.

Characteristic

- Good chemical resistant

- Good transparency & low yellow index

- Good moldability

- Low specific gravity

- Coloration

Features of STYLAC - Mechanical Properties (AS)

| Properties | standard | units | AS (SAN resin) | ||||

|---|---|---|---|---|---|---|---|

| General purpose | Heat resistant Chemical resistant |

Good surface appearance |

|||||

| 767 standard |

T8701 High flow |

789H standard |

703H High heat |

T8707 High transparency |

|||

| Melt volume-flow rate | ISO 1133 | ㎤ /10min | 13 | 25 | 29 | 10 | 32 |

| Tensile stress at yield | ISO 527-1 | MPa | 73 | 68 | 72 | 80 | 61 |

| Flexural modulus | ISO 178 | MPa | 3700 | 3650 | 3750 | 3750 | 3650 |

| Flexural strength | ISO 178 | MPa | 130 | 125 | 138 | 136 | 120 |

| Charpy impact strength(notched) |

ISO 179 | KJ/m² | 1.3 | 1.3 | 1.3 | 1.3 | 1.2 |

| vicat softening temperature |

ISO 306 | ℃ | 103 | 102 | 90 | 109 | 101 |

| Deflection temperature under load |

ISO 75-1,2 | ℃ | 88 | 87 | 1.08 | 92 | 86 |

| Density | ISO 1783 | g/㎤ | 1.07 | 1.07 | 1.08 | 1.08 | 1.07 |

| JHOPA | - | Asahi Low | registration | registration | registration | registration | |

Features of STYLAC - Mechanical Properties (ABS)

| Properties | standard | units | ABS | |

|---|---|---|---|---|

| Chemical resistant | ||||

| IX22P standard | IX60P High chemical resistant |

|||

| Melt volume-flow rate | ISO 1133 | ㎤ /10min | 16 | 8 |

| Tensile stress at yield | ISO 527-1 | MPa | 48 | 38 |

| Flexural modulus | ISO 178 | MPa | 2,400 | 1,850 |

| Flexural strength | ISO 178 | MPa | 74 | 58 |

| Charpy impact strength(notched) | ISO 179 | KJ/m² | 44 | 42 |

| Vicat softening temperature | ISO 306 | ℃ | 100 | 94 |

| Deflection temperature under load | ISO 75-1,2 | ℃ | 82 | 78 |

| Density | ISO 1783 | g/㎤ | 1.05 | 1.05 |

| JHOPA | - | registration | registration | |

The values in the above table are representative values obtained using the noted test methods.

Please use these values as a reference when selecting the most suitable grade

for each respective use.

Comparison of plastics

| Stylac ABS Chemical resistant |

Stylac AS Chemical resistant |

Amorphous Polyester |

PC | PMMA | ABS (Transparency ) ABS | |

|---|---|---|---|---|---|---|

| Chemical resistant | ◎ | ○ | ○ | △ | × | △ |

| Moldability | ◎ | ◎ | △ | △ | △ | ◎ |

| Stiffness | ○ | ◎ | △ | △ | ◎ | △ |

| Density | 1.05 | 1.08 | 1.2~1.3 | 13.2 | 1.19 | 1.12 |

| Transparency | unclarity | ◎ | ◎ | ◎ | ◎ | ○ |

| Impact | ◎ | △ | ◎ ~ △ | ◎ | △ | ○ |

Application Example

[ Grade ABSIX22P(White) ]

- chemical resistance

- Liquidity

- tone

[ Grade ABS-IX60P ]

- chemical Resistance

- tone